Publisher: Administrator Date: 2025-03-07

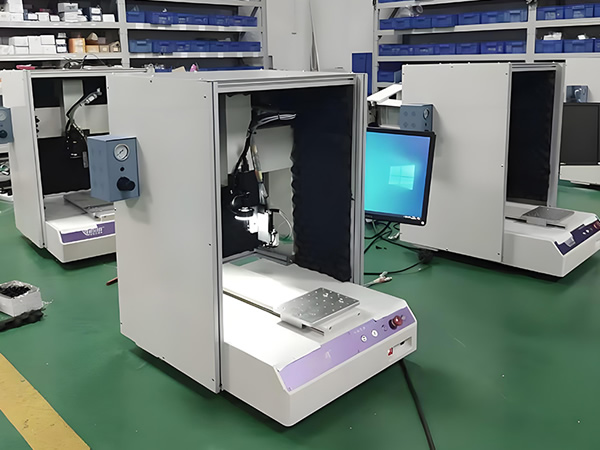

AutomaticDispenserDue to improper operation or lack of experience during the dispensing process, many details may arise. So, how can we effectively solve these problems? Dexin Automation will explain to you!

Mainly to explain the solutions to individual problems such as nozzle blockage, valve leakage, and bubbles in the fluid that occur during the dispensing process of automatic dispensing machines:

Problem 1: Rubber nozzle blockage

The problem of nozzle blockage is more common in the early use of automatic dispensing machine equipment. It can be said that this problem can occur due to manual operation without paying attention to details, which makes it easier to avoid:

reason:The blockage is mainly due to incomplete cleaning of the needle holes in the automatic dispensing machine, impurities mixed in the surface mount adhesive, and the phenomenon of hole blockage. Incompatible adhesives are mixed, resulting in insufficient or no adhesive dots coming out of the nozzle.

resolvent:Replace the dispensing needle, or clean the needle with a specialized cleaning agent after each dispensing operation is completed. In addition, try not to use the same needle for two different types of glue, as poor cleaning may cause the two adhesives to react and cause clogging of the nozzle.

Problem 2: Leakage of rubber valve

There are two situations where dripping occurs:

The needle diameter used in the dispensing machine is too small, and a needle that is too small can affect the exhaust bubble action when the glue valve starts to be used, affecting the flow of liquid and causing back pressure, resulting in dripping shortly after the glue valve is closed.

terms of settlement:Replacing the larger dispensing needle can solve such problems.

In addition, the following situations may cause dripping problems:

terms of settlement:Failure to stop the pneumatic conveying in a timely manner after the completion of the dispensing operation

The dispensing controller and valve body can be set up, and the dispensing valve and controller can be estimated to stop working a few tenths of a second in advance through testing. The leaked trace amount of glue can be calculated into the range required by the standard dispensing amount, thus achieving precise dispensing.

Question 3: There are bubbles in the fluid

reason:Bubbles during dispensing may occur when the air inside the syringe is not completely expelled before starting the dispensing process, or when the fluid pressure is too high and the valve opening time is too short, air may seep into the liquid, causing the formation of bubbles.

resolvent:The fluid pressure should be controlled reasonably, and a conical inclined needle can be used to avoid the generation of bubbles during dispensing.